UV technology

DR. FISCHER, experts in UV technology for your professional applications.

What is ultraviolet light?

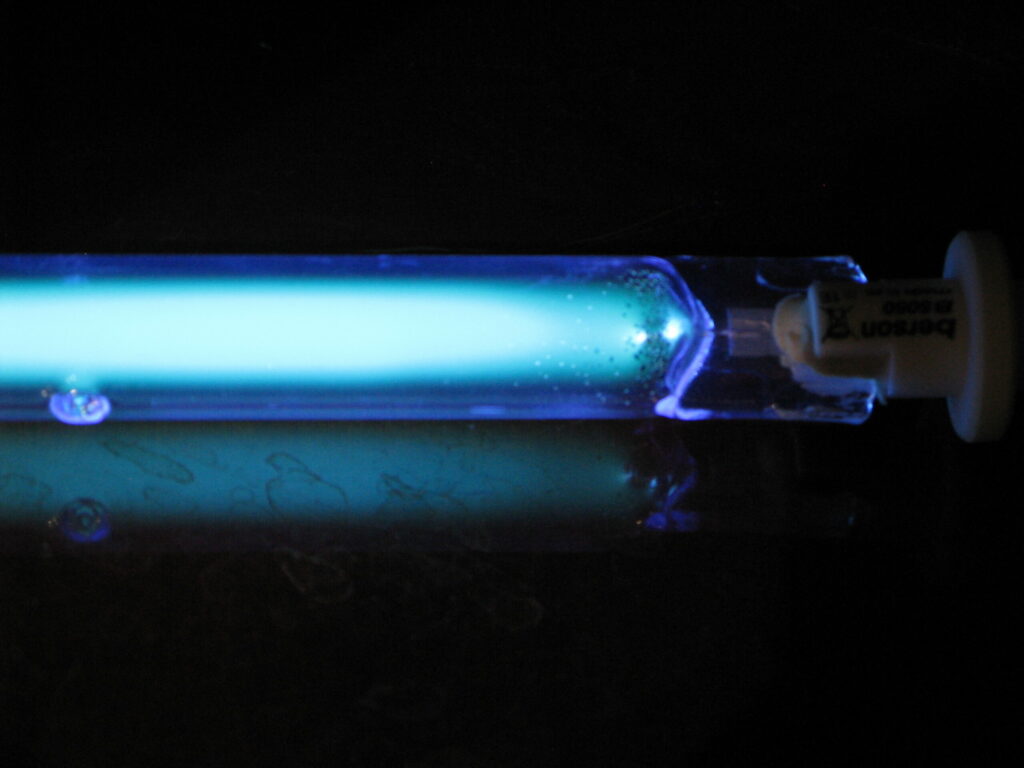

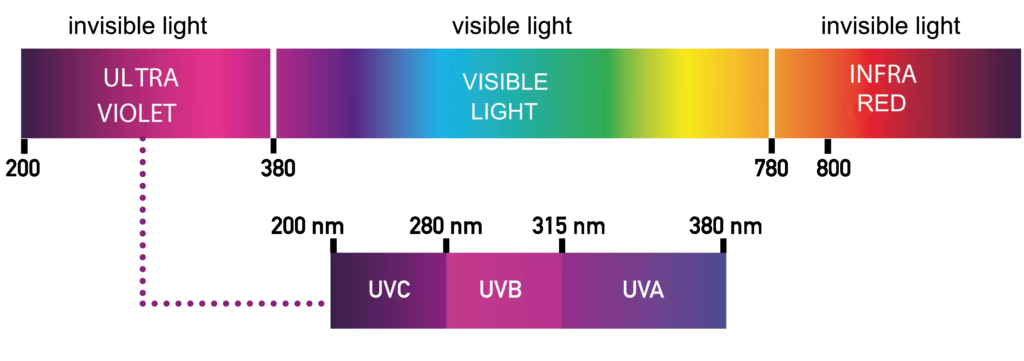

Ultraviolet light is the part of the electromagnetic spectrum between 200 & 380 nanometres. UV is non-visible energetic radiation expressed in W/cm².

It is created by a plasma arc resulting from the high-temperature vaporisation of the mercury contained in the lamp.

Its photochemical and biological effects have given rise to numerous industrial applications exploiting different areas of the UV spectrum.

The 3 zones of the UV spectrum are :

UV-A: 380 to 315 nm, e.g. paint curing,

UV-B: 315 to 280 nm, e.g. vitamin D synthesis,

UV-C: 280 to 200 nm, e.g. biocidal power: water disinfection

Precisely Tuned Light Spectrum: How Metal and Material Dopants Optimize UV Lamps and LEDs

UV lamps emit spectral rays whose wavelengths are adjusted by metal salts (dopants) such as gallium, iron, indium or lead, depending on the application, while LED wavelenth are adjusted by special dopings and material components.The nature of the quartz tube can also modify the spectrum of the lamp.

Find out more about our applications:

The main salts used and their respective spectra (in nm)

The advantages of UV

Ecological

Ecological

Investment

Investment

Easy-to-use

Easy-to-use

Expertise

Expertise

Unique rendering

Unique rendering

Secure

Secure

The main families of UV applications

UV is used in a wide range of sectors and has 2 main families of applications, as follows:

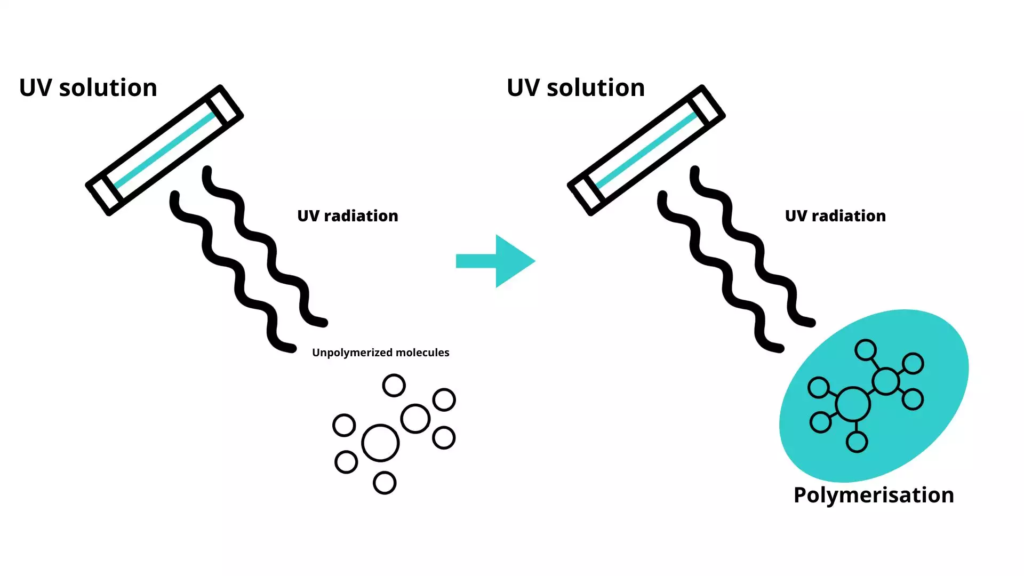

Polymerization, curing and UV treatment

UV treatment is a broad family of applications for UV radiation. Its main function is to modify the molecular structure of the surface exposed to UV radiation. In general, UV treatment is said to solidify the treated substrate, i.e. harden it.

This applies to several categories of applications such as :

UV curing generates a cross-linked network of polymers on the treated surface. A photochemical reaction then takes place. UV curing, also known as UV polymerisation, is a low-temperature process: the substrate is not heated and no evaporation occurs. The treatment time is faster than that of a drying oven, and no extraction of fumes is required.

Metallisation. UV radiation enables a primary varnish to adhere quickly to the substrate (glass or plastic): this is the UV curing process. This stage precedes the metallization process. To obtain a glossy, scratch-resistant appearance, a new UV treatment is required.

Offset printing involves the use of offset plates onto which an emulsion is deposited. During sheet production, this emulsion applied to the aluminium is rapidly polymerised using a UV treatment.

Screen printing is a specific printing process. The ink, deposited on a screen using a stencil, is spread using a counter doctor blade. UV radiation is used to set the ink pattern on the substrate. UV creates an unrivalled gloss.

There are various ways of generating UV radiation.

DR. FISCHER masters not only mercury lamp technology (low and medium pressure) and xenon lamps (pulsed light), but also LEDs. These technologies meet the majority of our customers’ needs.

UV germicidal treatment of surface, water and air

UV-C germicidal solutions can be used to treat air, water or any type of surface. UV-C is used to eradicate all bacteria, viruses, mould, germs and other parasitic molecules. UV-C has the advantage of being extremely effective in eradicating micro-organisms, and is fairly easy to set up.

The germicidal effect of UV radiation is simple: UV-C inactivates viruses and micro-organisms such as moulds, spores and yeasts by destroying their DNA or RNA (a molecule that makes up the genome in some viruses). The peak of germicidal efficacy occurs between 260 and 280 nm.

Another major advantage of using UV-C is that it avoids putting chemicals on the treated surface, or into the air or water.

The UV treatments offered by DR. FISCHER products can be fungicidal, bactericidal or virucidal.

There are many examples of UV decontamination applications such as :

- UV decontamination of food packaging

- UV treatment of ballast water for boats

- UV disinfection of aquaculture ponds

- UV decontamination of swimming pools

- UV disinfection of waste water

- UV decontamination of pharmaceutical laboratory water

- UV water purification

- UV decontamination of drinks before bottling

- UV air decontamination (elimination of COVID-19)

Other applications are possible, so don’t hesitate to contact us to find out more!

Tailor-made UV solutions

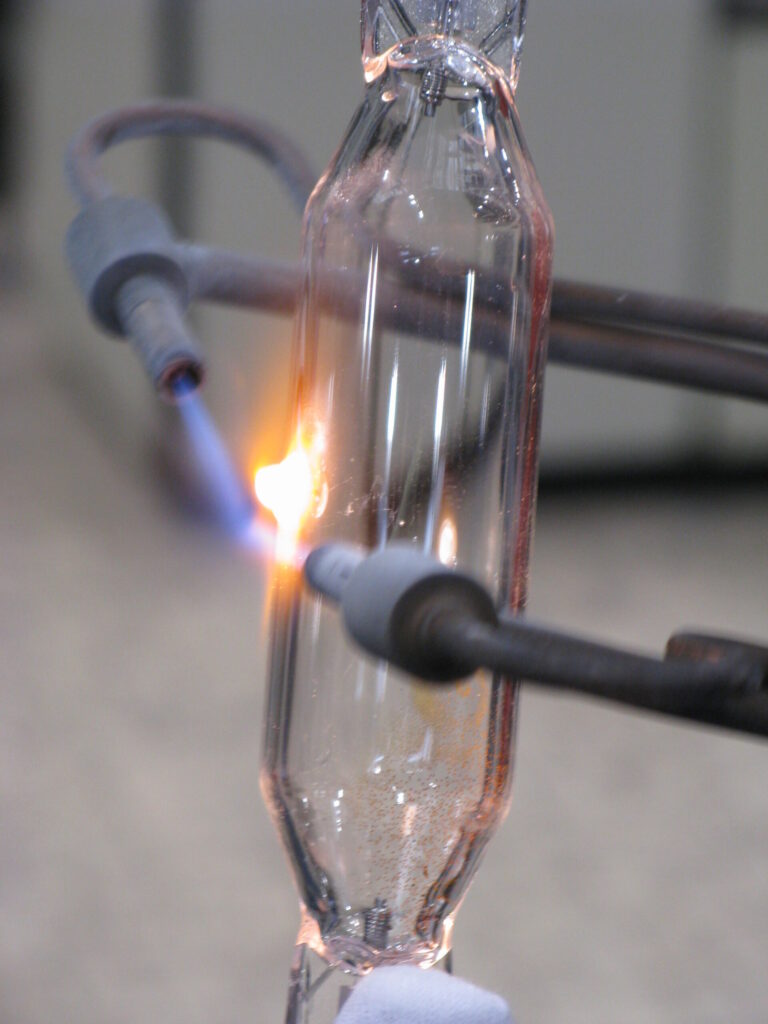

The production of UV lamps

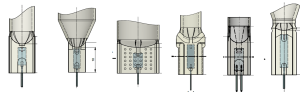

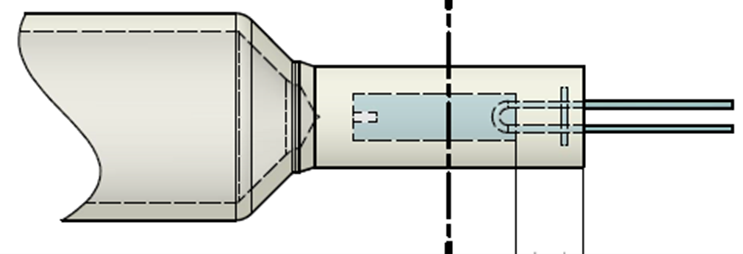

1. Lamp sealing and sealing solutions

We offer two types of seals:

Pinching

- Compact lamp

- Cost-effective process

Shrink sealing

- Variable sealing length

- Possibility of asymmetrical lamp

2. Lamp filling

DR. FISCHER, an expert in lamp production for decades, applies advanced production processes to achieve impeccable levels of purity.

Particular care is taken when filling the lamps, with multiple pumping cycles at high temperatures to guarantee long life and high performance.

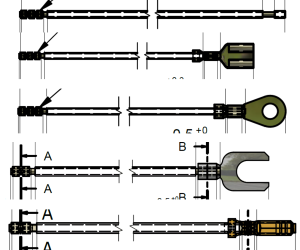

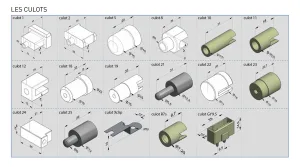

3. UV lamp connections

A wide range of bases and connections are available from DR. FISCHER, examples of which can be found below:

Contact us

Located in Pont-à-Mousson in Eastern France, it is the largest factory of the group. This entity is also the largest European center of expertise that develops, manufactures, and markets infrared heating lamps and modules, UV lamps and modules, halogen lamps, as well as LED solutions.