The IR technology

DR. FISCHER Europe, a complete range of

infrared lamps and systems.

Why choosing infrared?

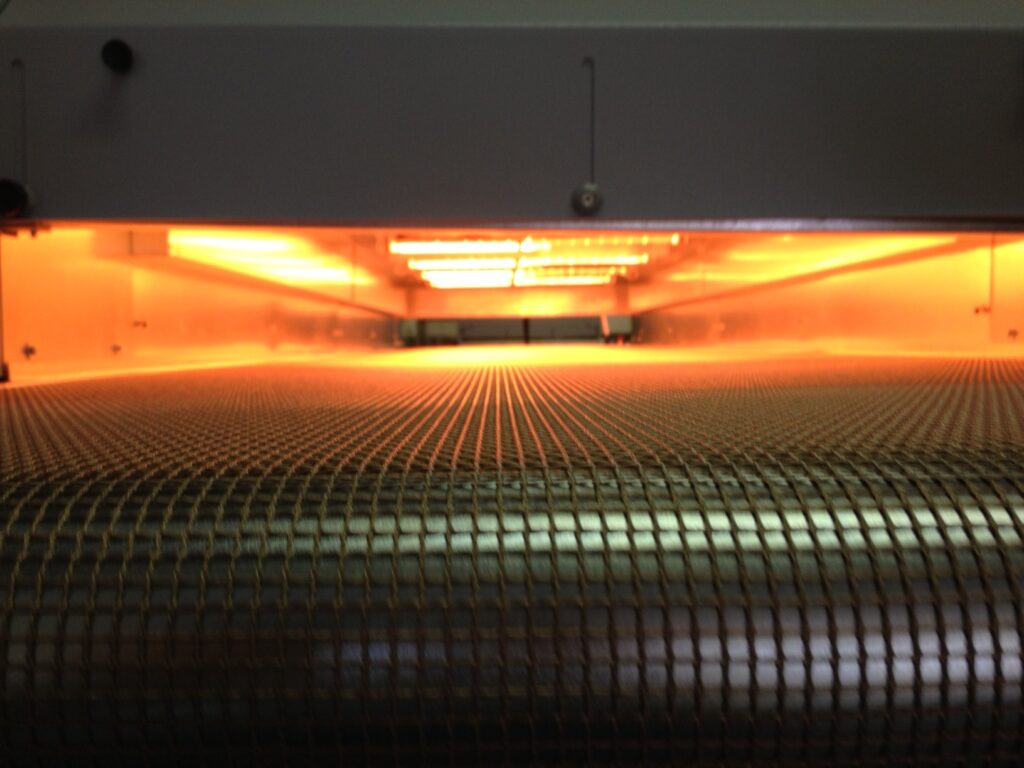

The IR solutions DR. FISCHER operate according to the principle of radiation.

Infrared radiation directly heats the objects or people towards which it is directed without heating the surrounding air.

It is a very efficient contactless heat source.

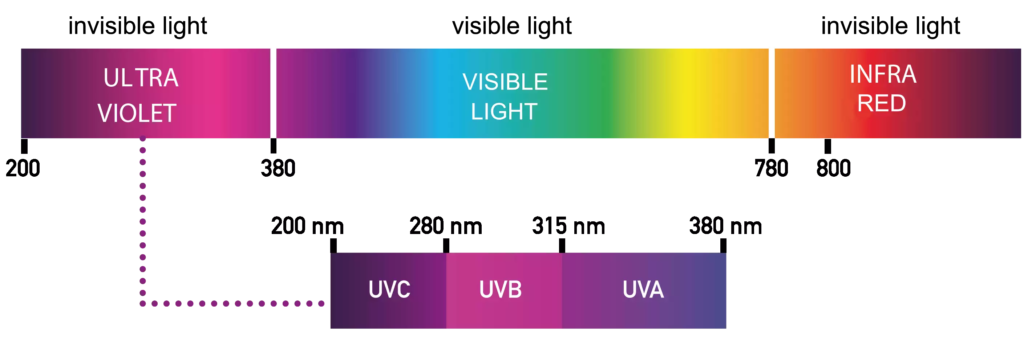

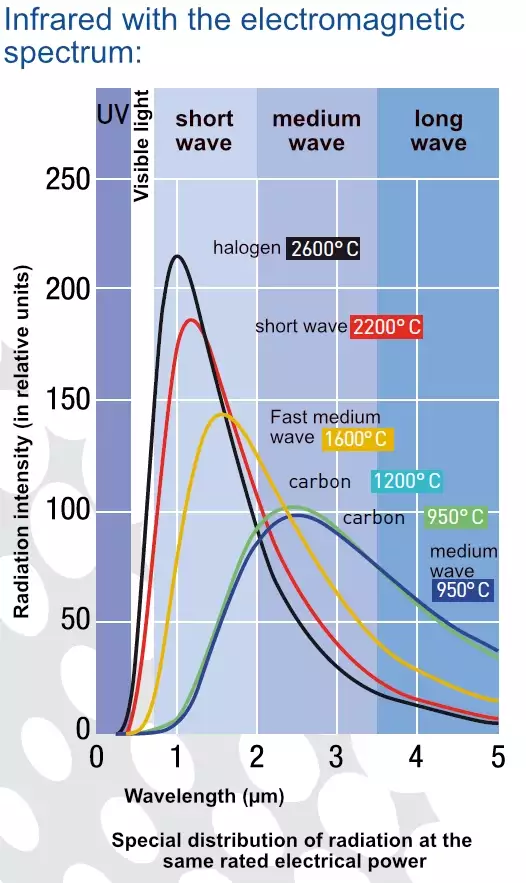

Infrared is divided into 3 categories:

- IR-A (shortwave) 800 to 1400 nm

- IR-B (medium & medium fast waves) from 1,400 to 3,000 nm

- IR-C (longwave) from 3,000 to 10,000 nm

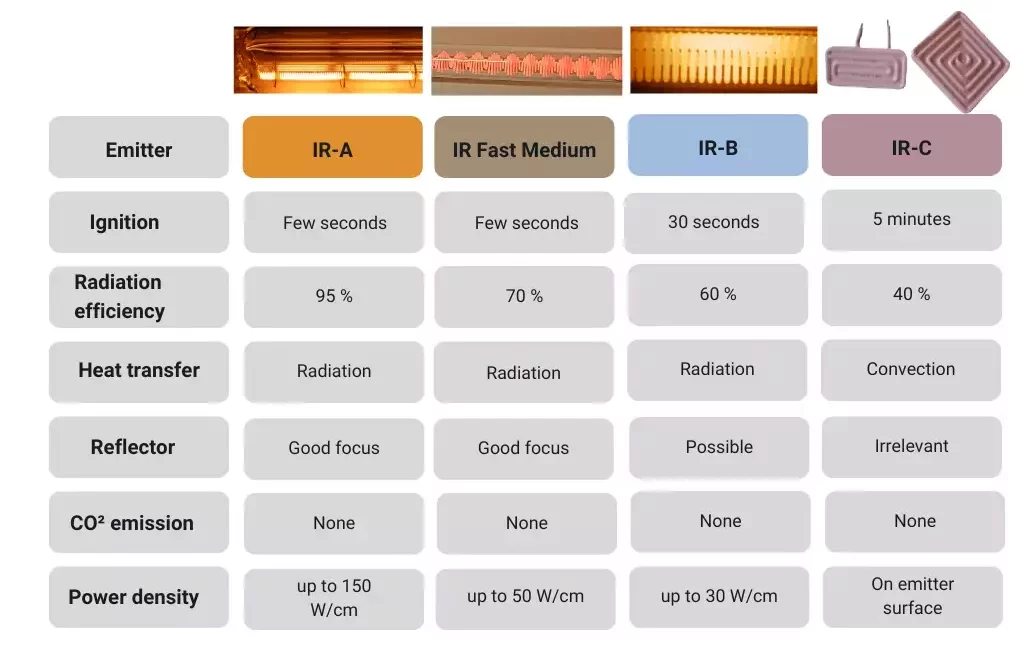

IR emitter types:

Comparison of IR emitter types

DR. FISCHER supports you in choosing the best IR technology, depending on your application, and the materials to be heated

(after absorption measurements carried out in our laboratory).

We develop specifications for the optimal solution jointly with our customers. (Mechanical and electronic integration, planning, objectives, etc.)

To find out more, do not hesitate to inform yourself via our articles.

Infrared application families

Click on one of these application families to find out more about the possibilities enabled by infrared:

Food

In the food and catering sectors, there are many processes requiring heat, both for food and its packaging:

Dishes that are already ready may need to be browned in the oven to make them more attractive to consumers. Infrared is then an ideal solution for instantly heating food without excess energy consumption.

Food packaging, often made of plastic, metal or paper, requires a heat source so that its coating can dry quickly. The food is thus better isolated from the outside and potential sources of bacteria. Keeping containers warm in collective or industrial kitchens can be ensured by infrared systems. An infrared grill in catering is an alternative cooking solution.

DR. FISCHER offers tailor-made solutions to meet the needs for precise and controllable heat sources for companies in the food sector.

Wellbeing & Pets

Infrared has famous virtues among fans of infrared therapy.

Infrared penetrates the skin deeply and gently, and has anti-inflammatory, analgesic and antispasmodic properties. Infrared allows you to treat a sore area of the body in depth, by heating the painful muscles.

Infrared saunas, or infrared cabins, are a common practice in some countries. These atypical places of relaxation allow, like traditional saunas, the detoxification of the body, the reduction of cellulite, the relief of muscle and joint pain and the improvement of the immune system.

Zone heating is one of the most widespread practices in the world for the general infrared public. The infrared lamp turns on instantly and regularly heats an area outdoors, or even indoors, without heating the air, and just long enough for a user to be present. Many places use this such as offices, terraces or even churches.

That is why DR. FISCHER offers its range of VITAE infrared lamps and solutions, solutions specially designed for saunas. These diffused light solutions prevent infrared risks thanks to filtering technology, in order to make the products more aesthetic, but above all more comfortable and adapted to the human body.

Reptiles in vivariums need infrared rays in order to live in an environment that suits them. These living beings have specific needs that infrared solutions meet perfectly!

Horses, for their health, can benefit from the benefits of a solarium. These solutions help keep muscles warm after exercise as well as improve the coat of animals! They are also kept warm during periods of extreme cold.

Industrial coating & drying

Coatings need to be dried in a very specific way, depending on their characteristics. Most often, these are water-based varnishes, paints, powders, lacquers, etc. Drying is very present in the industry and requires that we pay great attention to it if we want to increase our output and productivity while avoiding the risk of errors.

The glass industry and bottlemaking often require decoration using sprays. Infrared ovens allow the screen prints on the bottles to be dried.

Printing often requires creating hundreds of copies at high speed. Drying the paper is one of the key steps in printing so that the ink does not bleed and remains professional quality.

Semiconductors have a very close connection with infrared drying. This may be necessary for drying a silicon coating layer as well as for drying wafers used in the manufacturing processes of electronic components. Solar panels can be made using IR rays! Infrared solutions create the CIGS cells found in solar panels by drying the anti-reflective coatings on their surface. This process requires high heat, but above all heating uniformity over a large surface, which infrared technology allows.

Anti-slip coatings found on many surfaces can be dried using infrared very quickly. Traffic signs have aluminum coatings on their surface. An infrared oven can dry these quickly. Car bumpers can be made faster using infrared. Infrared technology helps speed up the drying process of automobile bumper coatings. Paint is used in many trades. A portable infrared dryer enables it to be dried very quickly, speeding up production. Glass, metal, textiles and wood are other materials that sometimes require a coating to be dried on top.

At DR. FISCHER, we specialise in tailor-made solutions for fast and accurate drying of coatings and coatings.

Adhesive

Infrared emitters are frequently used to heat-activate adhesives.

Substrates may also need to be preheated quickly before an industrial process. This pre-heating is achieved using infrared, a rapid heating technology. The infrared radiation emitted by our solutions can be used to bond a variety of materials, including paper and cardboard. Thermobonding is a recurrent practice in the textile industry for assembling parts. This applies equally to the footwear industry and to clothing. Coatings are applied to the textile and heated to temperatures approaching hundreds of degrees Celsius.

At DR. FISCHER, we offer tailor-made infrared solutions to meet the productivity needs of manufacturers.

Plastic

Plastic is a material with many heating applications.

PET bottle blow moulding is one of the key applications for infrared. DR. FISCHER is an ideal partner in this industrial process. Plastic bottle preforms are pre-heated before being blown, and this pre-heating must be meticulous in order to heat certain parts of the preform more than others.

Thermoforming is a technique used to shape plastic as desired. This process requires a rapid influx of heat over a short period of time. Infrared is therefore an ideal solution for plastic thermoforming processes. Plastic welding is used in many industries. The heat emitted by the infrared rays enables pieces of plastic to be joined together without any excess particles.

At DR. FISCHER, heating plastics is one of our key areas of expertise. Every day, we produce tailor-made solutions for our customers around the world.

Simulation & Vegetation

An element irradiated by infrared radiation is kept warm.

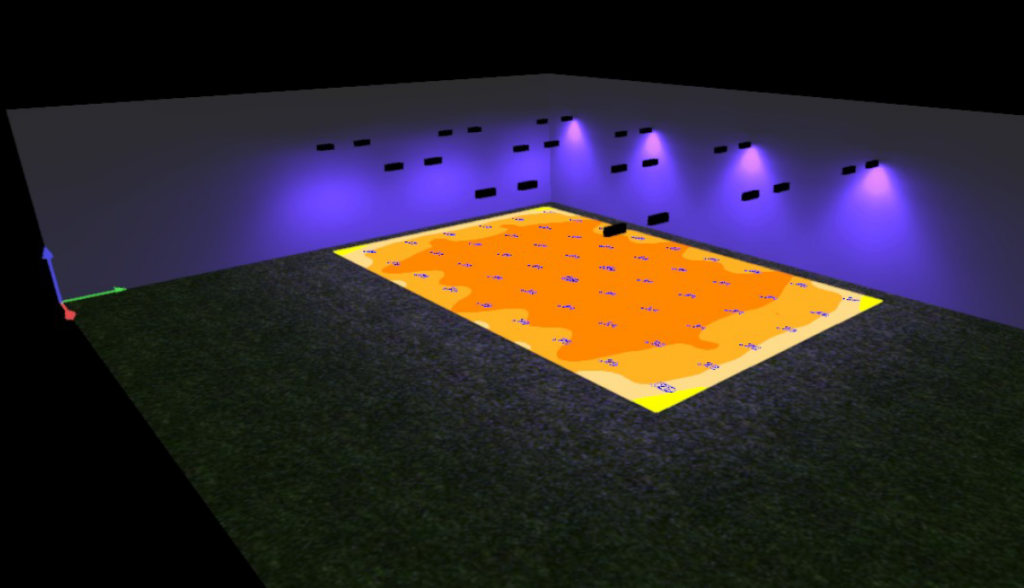

In this way, infrared solutions can be adapted to the intrinsic needs of plants, but also to gas power plants and air filters. Horticulture involves heating plants, such as vegetables, to maximise their growth potential. Infrared heating replicates the ideal environmental conditions for plant growth. Lawns in sports stadiums need a lot more maintenance than they appear to have in order to remain impeccable!

DR. FISCHER is a partner of many stadiums for turf heating in winter. As a result, the lawn remains in excellent condition for sporting events, and requires less maintenance whatever the season. Climatic chambers are large rooms heated by infrared to reproduce climatic conditions on objects such as cars.

With DR. FISCHER, you have a partner of choice for your occasional heat source needs. You save energy and money by choosing our customised solutions that can be controlled and programmed exactly to your needs!

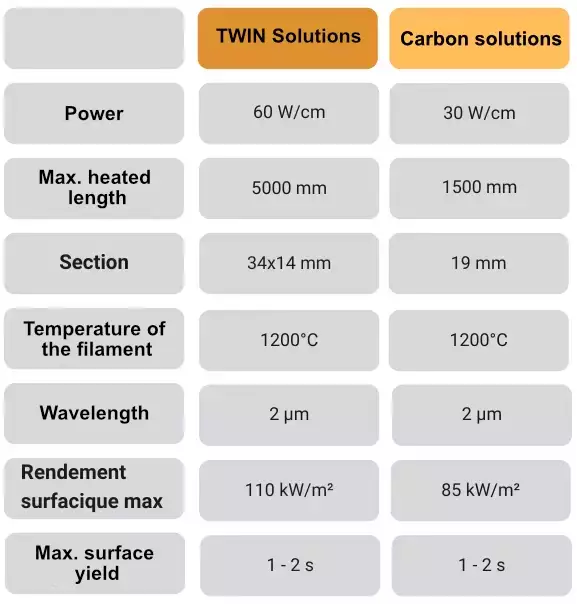

Infrared technical specifications

The laws of physics are our only limit, and this table shows the potential of our infrared solutions.

Can’t find your features? Contact us!

DR. FISCHER and you

At DR. At FISCHER, we work closely with our customers.

DR. FISCHER is: a sales team that listens to you, supported by an R&D department of qualified engineers trained in cutting-edge technologies; Personalised support, simulation equipment, prototyping, etc.

We can provide high-performance infrared solutions to meet individual requirements. The design office of DR. FISCHER is the place where your projects come to life.

DR. FISCHER can provide you with expert advice and help you to carry out numerical simulations so that you can understand your needs as accurately as possible.

DR. FISCHER is ISO 14001 & ISO 9001 certified. (click to see our certifications)

Contact us

Located in Pont-à-Mousson in Eastern France, it is the largest factory of the group. This entity is also the largest European center of expertise that develops, manufactures, and markets infrared heating lamps and modules, UV lamps and modules, halogen lamps, as well as LED solutions.