The advantages of infrared drying in the industrial sector

Your company can improve its production thanks to infrared technology.

Infrared is an asset in the world of industry. A major property of infrared is its ability to dry materials quickly.

Does your company need coating in its processes? Infrared drying removes water-based or solvent-based products from your product.

Infrared drying saves money by speeding up production and reducing certain costs.

However, the infrared solution must be adapted to the specific needs of the heated surface.

This article will show you who IR drying is for, its benefits, how it works and the best infrared solutions for growing your business.

Contents

Infrared drying applications

Infrared drying has various applications, such as :

- Printing to dry the ink on the paper or any other material

- Cars for drying body paint or upholstery

- Perfume to dry varnish on bottles

- Textiles for screen printing on clothing or other textile objects

- Shoes for accelerated glue drying

- Spirits for drying bottles

- Food processing to dry certain foods or analyse their water content

- Semiconductors to dry printed circuits

- Paper to dry adhesive residues

- Metallurgy to dry coatings

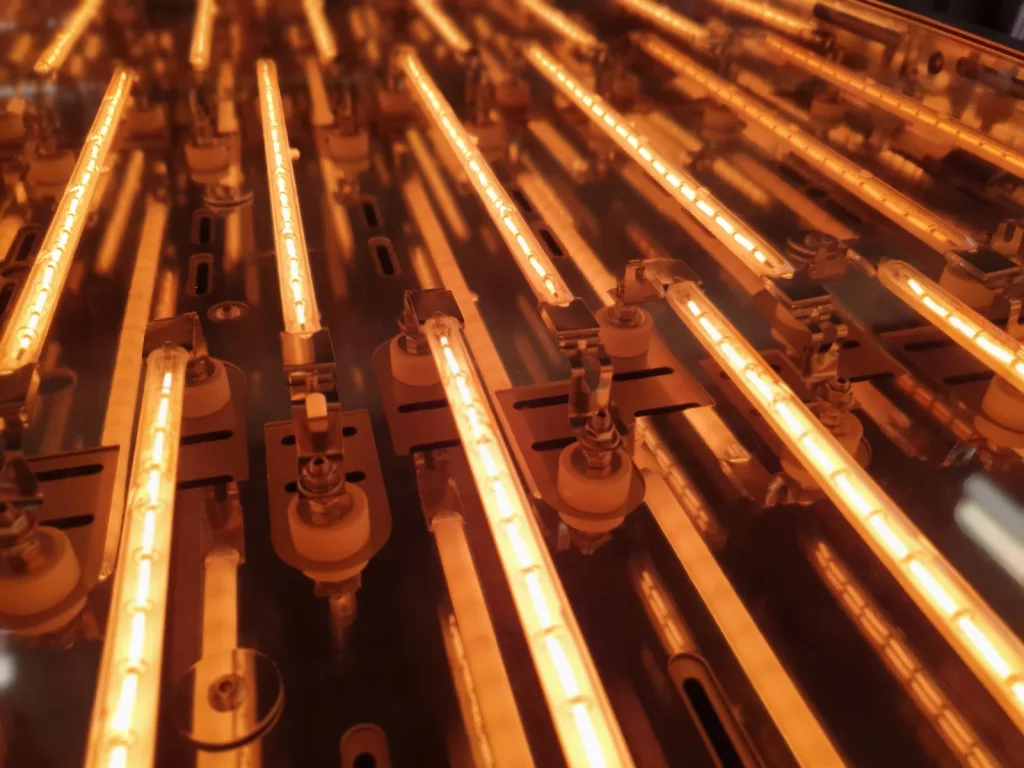

Infrared lamps DR. FISCHER products are also used by manufacturers of drying machines.

Do you belong to one of these business sectors? The rest will interest you.

Improve your business with infrared drying

Infrared drying saves manufacturers time and money:

This technology has a number of decisive advantages, including :

- Accelerated production

- No contact necessary with the product to be dried

- Lights up in less than a second

- High power, even on small surfaces

- Excellent heat transmission

- Easy to control

- Adaptability

- Improved quality of finished product

If you are using a hot air or gas solution, using infrared is an excellent opportunity to achieve a more compact drying space and greater efficiency.

Description of infrared drying

Infrared is easy to control, so it can be perfectly adapted to any application.

The main characteristic of infrared is its wavelength, which can be :

- Short infrared: from 0.78µm to 2µm

- Mid-infrared: from 2µm to 4µm

- Long infrared: from 4µm to 1000µm

Its wavelength can be modified to match the absorption peak of water molecules.

Most often, short- or medium-wave IR is used for drying.

Tailor-made solutions are available to make the infrared dryer as efficient as possible.

The radiation emitted by the dryer does not need air as a support: it hits the target molecules directly.

As a result, the air is not affected, and heat is transmitted with speed and precision!

Which infrared heater should I choose?

With over 40 years’ experience in infrared, DR. FISCHER is an expert in customised infrared solutions.

We’re your ideal partner for improving your business!

Infrared dryers from DR. FISCHER products are competitive and already approved by many manufacturers.

Our teams of developers can offer you solutions tailored to the needs of your business.

DR. FISCHER offers its customers a small MOQ and short delivery times.

We also know that price is the sinews of war, especially in certain sectors such as textiles: we keep within a low range to ensure that you are as profitable as possible.